Image courtesy of Northwest Electric & Solar

Whenever we speak to solar contractors, they inevitably ask us how accurate Scanifly’s solar design software really is. We understand the concern! We used to be solar surveyors, designers, and installers ourselves. And we know there’s a certain confidence that comes from touching the roof with your own hands.

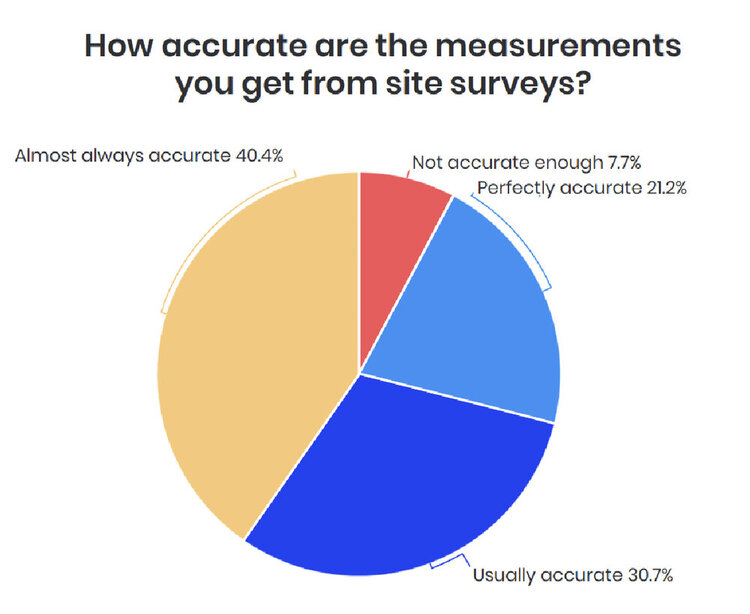

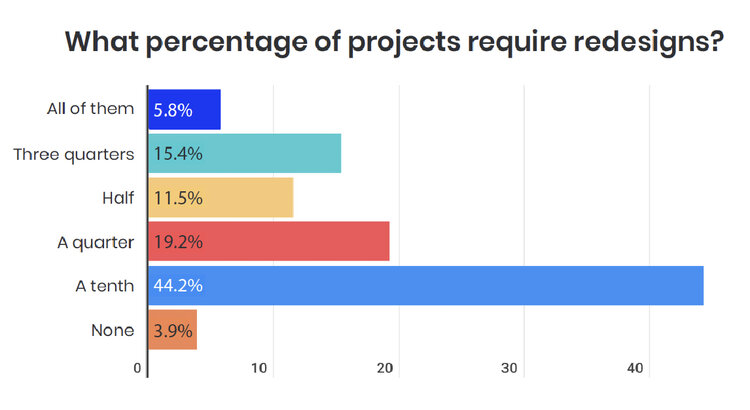

However, the reality is that human error is inevitable and causes problems, especially as a business grows: 71% of hand-determined measurements are “usually accurate” or “almost always accurate”. This insinuates that hand-drawn measurements aren’t accurate enough. And over half of solar contractors say that 25% of their projects require redesigns (You can see all this data and more in our 2021 Solar Surveyor and Designer Outlook.

At Scanifly, we stand behind our Accuracy Pledge – and have many solar contractors who publicly stand behind it as well. Here’s how it works from a quantitative and qualitative perspective.

The quantitative: Accurate to within 2-3 inches

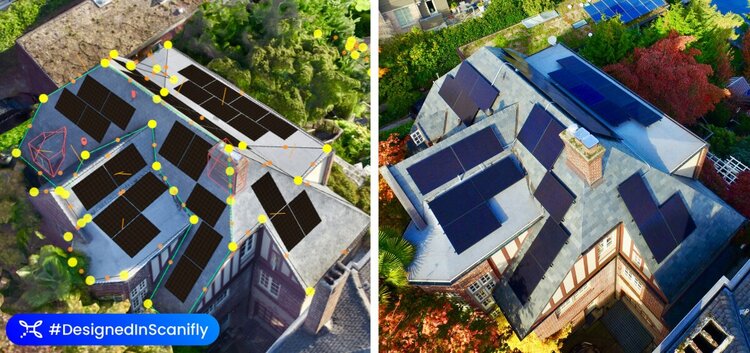

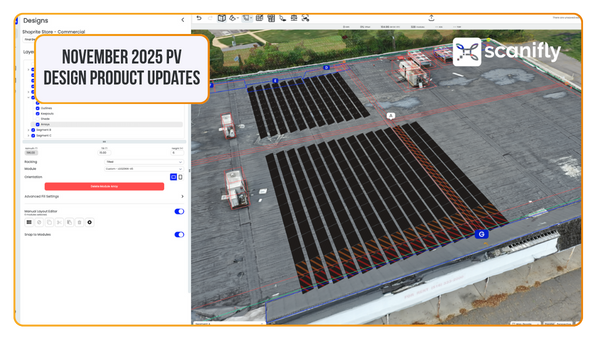

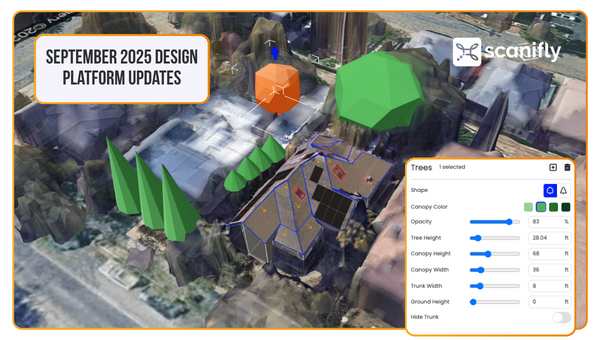

Scanifly’s software uses a process called photogrammetry (explanation video here): First, a drone takes several hundred pictures (i.e. JPEGs) of a building – from every angle possible. Then, the software automatically stitches together the images by looking at colors, keypoints and the location data imprinted in the underlying images. This produces a to-scale, virtual replica 3D model of the property. From there, Scanifly users can measure anything in the 3D space, design a solar array, and export wireframes to AutoCAD and SketchUp, among many other things.

The accuracy of Scanifly’s platform, which is reflective of the precision of photogrammetry, is 2-3 inches across the X-Y-Z planes. This allows users in the software to granularly measure roof planes, vent pipes, skylights, chimneys, and other rooftop obstructions. Designers can get measurements in a consistent methodology and not question exactly where the tape measure was placed.

We also validate our accuracy pledge after each significant software upgrade by going on the roof and comparing the physical world with Scanifly’s software’s virtual world.

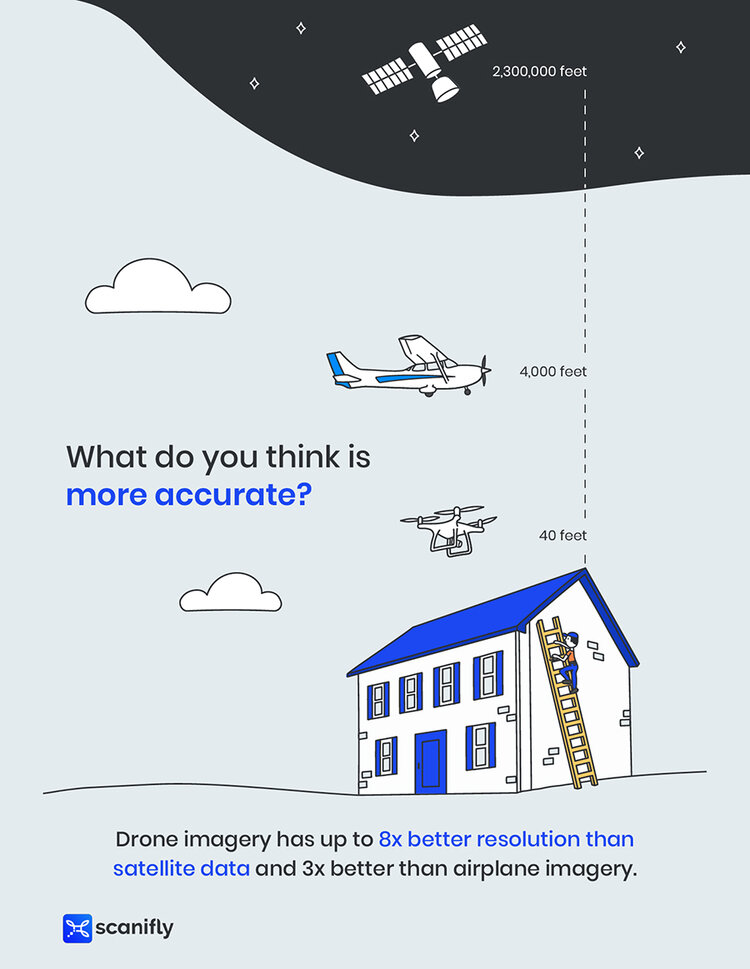

The Qualitative: Perfect Accuracy = No Change Orders or Redesigns

When people ask us how they can prove Scanifly’s accuracy for themselves, we suggest doing a drone survey on a property they’ve already measured correctly by hand and uploading the drone images to Scanifly’s platform for assessment. When we spoke with existing customers about Scanifly’s accuracy, they shared that Scanifly is perfectly accurate, and didn’t yield any redesigns, change orders, or additional truck rolls to complete the project. One customer, Jim Jenal of Run on Sun, wrote a blog post on the platform’s accuracy itself. And it sure beats the accuracy of satellite imagery or airplane data.

Customers also told Scanifly that drones make surveys 5x more efficient, meaning they can jump from doing 1-2 surveys to over 10 per day. Further, contractors using Scanifly report that drones are a fun experience for customers and deliver a significant cool factor for their businesses.

Finally, after project completion, we like to compare the Scanifly 3D model to the as-built diagram. In most cases, you can’t tell the difference between the two because the Scanifly model is so accurate.

Accuracy is everything

We know that accuracy is critical for solar contractors. It’s not just about the customer experience and trust, but also the raw financials. The average residential change order is $750; however, a significant one could wipe out a project’s return on investment, and ruin future relationships in that market. That’s why we use the most advanced technology we can – and fine tune it at every chance we get.